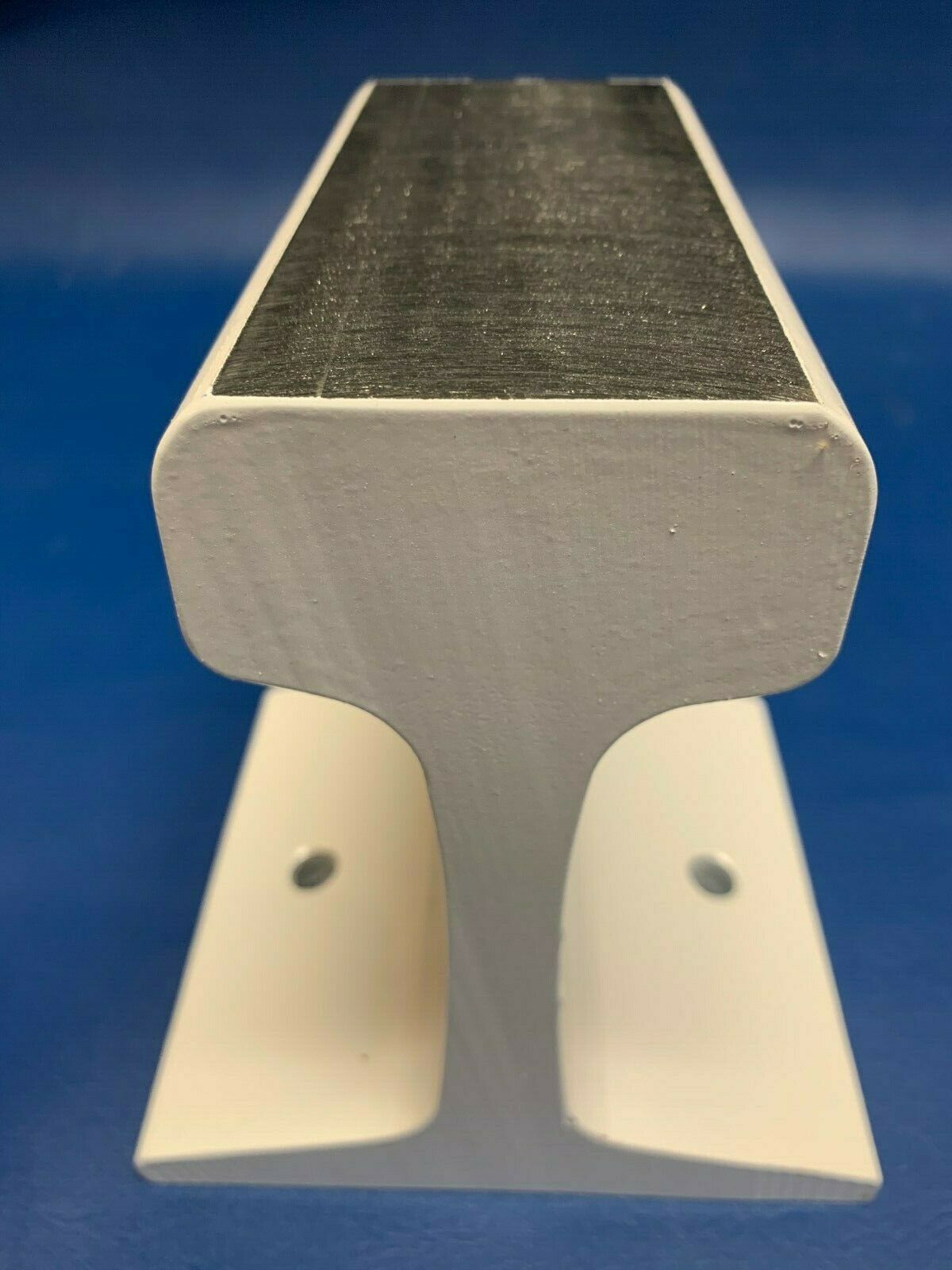

Grind the web into a fuller (radiused) shape.

While this short length of 10" to 12" will only weigh about 30 to 40 pounds it will react like an anvil about twice that weight. In this case the 90 to 120 pounds of rail will react to your blows like a 200 to 300 pound anvil.Ģ) The second method (middle) shows a typical short section of rail mounted on a tree stump using RR-spikes. So for forging up to about 3" bar stock the end of the rail is all you need!Ībove are three ways to mount a piece of rail.ġ) IF you have a choice and can get a piece cut the length you need then a 28" long (or a little over knuckle height) piece of rail will weigh about 100 pounds which is a nice anvil weight, ESPECIALLY if most of it is under the hammer blow. However, this small spot, just a few times larger than the face of the hammer, is just as big as the "sweet spot" that most smiths find on their anvils and use for 90% of their work.Īs long as this area is larger than what you are hammering on then it is more than you need. YES, this makes the working surface small. These now become good mass with a high efficiency. This puts 50% of the rail directly under the blow and takes the spring out of the connection between it and the web and flange.

To put MASS under the hammer blow you turn the rail on end. The radiused surface is something only Chinese smiths appreciate. This is because they put no mass under the hammer blow and the narrow web makes them very springy. Typical horizotal railroad rail anvils are miserable things.

0 kommentar(er)

0 kommentar(er)